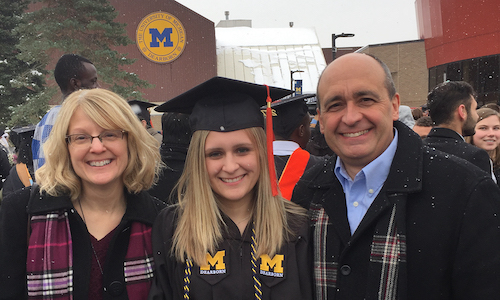

Victoria Sears held the prototype of a life-saving device in her hand. Looking at the tiny airway splint—made from a 3-D printer—she realized the importance of her bioengineering major.

“This tracheal splint saved a baby’s life. Doctors were able to fabricate a device that was successful when there were no other options,” said Sears, who had an internship at SME in Dearborn, where the splint was created. “I wanted to do more than work in the medical field, I wanted to make a contribution. I wanted to improve it; do something that is life changing.”

Sears, a College of Engineering and Computer Science student who will pursue her bioengineering graduate degree on campus this winter, said she discovered her major of choice through courses, internships and research opportunities.

“I thought about biology, but after taking some classes, I wanted it to be more math- and puzzle-solving orientated. I thought about engineering, but I wanted to help people directly—something with a healthcare impact. After exploring what the university had to offer, I sat down with a bioengineering professor and learned more about the field. I felt it was right for me.”

Prior to Sears’ sophomore year, she landed a summer research internship at Ford Motor Co., where she tested synthetic materials and gathered data. There, she first had access to a 3-D printer.

“I didn’t fully realize the medical effect it could have at the time, but I found it interesting and, after the internship was over, wanted to work more with 3-D printing,” said Sears, who completed four internships as an undergraduate, two at Ford and one each at SME and 3D Systems Healthcare.

Sears credits her junior year internship at SME for showing her how the 3-D printing technology could advance the medical field.

She saw 3-D printers make prosthesis in a fraction of the typical manufacturing time. Custom-to-patient 3-D heart models were fabricated for doctors to examine prior to a surgery. And that tiny biodegradable airway splint gave a 6-week-old baby with a rare condition the chance to be a now-healthy 5-year-old kindergartener.

“What I saw was just incredible,” she said.

From connections made during her internship at SME, she was offered and accepted a biomedical engineering internship at 3D Systems Healthcare in Colorado. Through this position, she gained hands-on experience with 3D printing in the medical field.

“When you are doing something that helps contribute to someone having a successful outcome, you feel like you are making a difference. It’s time well spent,” she said. “Knowing these are things I could do in this field solidified my choice.”

She said the caliber of experiences and opportunities shared with her at UM-Dearborn encouraged her to pursue a graduate degree on campus. The faculty, classes and guidance she received helped shaped her future—which, in turn, she hopes will have an impact on the lives of others.

“My professors helped me build a foundation in the field, expand my network and increase my confidence. I’m ready to learn more,” she said. “Printing to assist the medical field—3-D printing and bioprinting—is a new world that’s currently developing. There’s much room for improvement and innovation, and I hope I get to be a part of that.”