A custom-designed technology created on campus has the ability to transform the alternative energy landscape.

Mechanical Engineering Assistant Professor Nilay Chakraborty has developed a way to easily distribute bacteria—once too fragile for transport—proven to assimilate carbon in usable forms like biofuel.

This research, done in Chakraborty’s Cellular Bioprocessing Lab in the Engineering Laboratory Building, is the first work that shows a way to stabilize and keep an arid-sensitive anaerobic bacteria—Clostridium ljungdahlii—in a dry state, which makes it more accessible for use.

The research, which was in partnership with Professor Michael Flickinger at North Carolina State University, has a two-fold benefit—creating a new energy resource and converting an otherwise harmful carbon source into something useful.

Chakraborty said this bacteria can convert carbon monoxide into ethanol, which can be used as an additive to traditional fuel.

“We humans want to use energy to get something useful for it, like drive a car or fly an airplane. But, as we know, fossil fuel, takes millions of years to get created and has a finite pool that can get exhausted.”

Chakraborty said Clostridium ljungdahlii has the potential of many alternative energy applications—but there won’t be widespread benefit if it can’t be effectively distributed.

“Because of the sensitivity to oxygen, it is fragile. This bacterial strain needed very specialized equipment, which meant this addition to the alternative energy landscape couldn’t be easily shared,” said Chakraborty, noting it needed to be stored and transported at cryogenic conditions at more than negative 100 degrees Fahrenheit. “The key to the finding was using a unique scheme of metabolic strategies to stabilize the bacteria in a dry state, also known as lyopreservation.”

Chakraborty’s role in the research was to create a solution for effective stabilization and transportation of the bacteria without needing dry ice or liquid nitrogen to stabilize it.

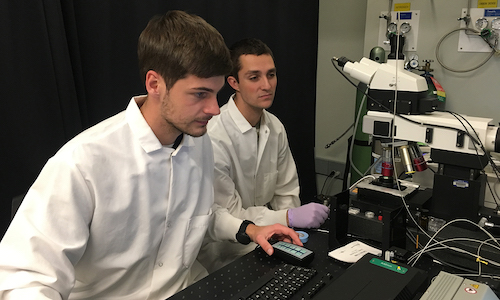

He and his research lab assistants—both graduate and undergraduate students—worked for three years to find the right preservation strategy.

One of the critical components of the technology that was developed at Flickinger’s laboratory is to create a solid-state bioreactor, which uses unwoven paper as a substrate.

After two years of research, Chakraborty’s group zeroed in on a strategy that worked. When rehydrated, the once dried bacteria functioned as expected and was successful is turning the carbon monoxide into a usable ethanol.

“There was a moment of ‘wow’ when we saw that the cells survived,” said Chakraborty of the late 2015 discovery. “But then we had to get back to work and make sure this result was consistent.”

It was. After several successful rounds, the research team called it proven.

The paper, “A technique for lyopreservation of Clostridium ljungdahlii in a biocomposite matrix for CO absorption,” was published in PLOS One science journal earlier this year.

Chakraborty stressed the importance of involving students in scientific and applied research.

The project involved two graduate students Jason Solocinski, who plans on completing his doctoral studies at UM-Dearborn, and Mian Wang; and two undergraduate bioengineering students, Quinn Osgood and Lukas Underwood.

Underwood said he asked his professor if there was “anything particularly interesting” Chakraborty was working on—and Underwood was given unexpected response.

“He not only told me what he was doing, he gave me the opportunity to get involved,” said Underwood, who graduated in 2016 and recently applied to pursue his Ph.D. in bioengineering at UM-Dearborn. “Because of Dr. Chakraborty, I was able to work on a research project that’s more than interesting; it has the to potential to be revolutionary.”

The research received funding from the National Science Foundation, the National Institutes of Health Molecular Biotechnology Training Program, the Department of Energy Efficiency and Renewable Energy, and the Golden LEAF Biotechnology Training and Education Center.