Supply base concentration and supply chain resilience sound like high-level logistics glossary terms — but their effect can be felt on the ground.

If there’s a computer chip shortage, you’ll have to wait for the vehicle you ordered. If stores don’t have enough toilet paper in stock, you can’t buy a household need. And, more important: When you are a business owner, these supply chain terms impact your life in ways that are more than inconvenient — it can lead to bankruptcy or closure.

Seeing how a global pandemic has caused disruption to the supply chain led College of Business professors to ask the question, “What can be done to improve the supply chain process so that it can better weather catastrophic circumstances?”

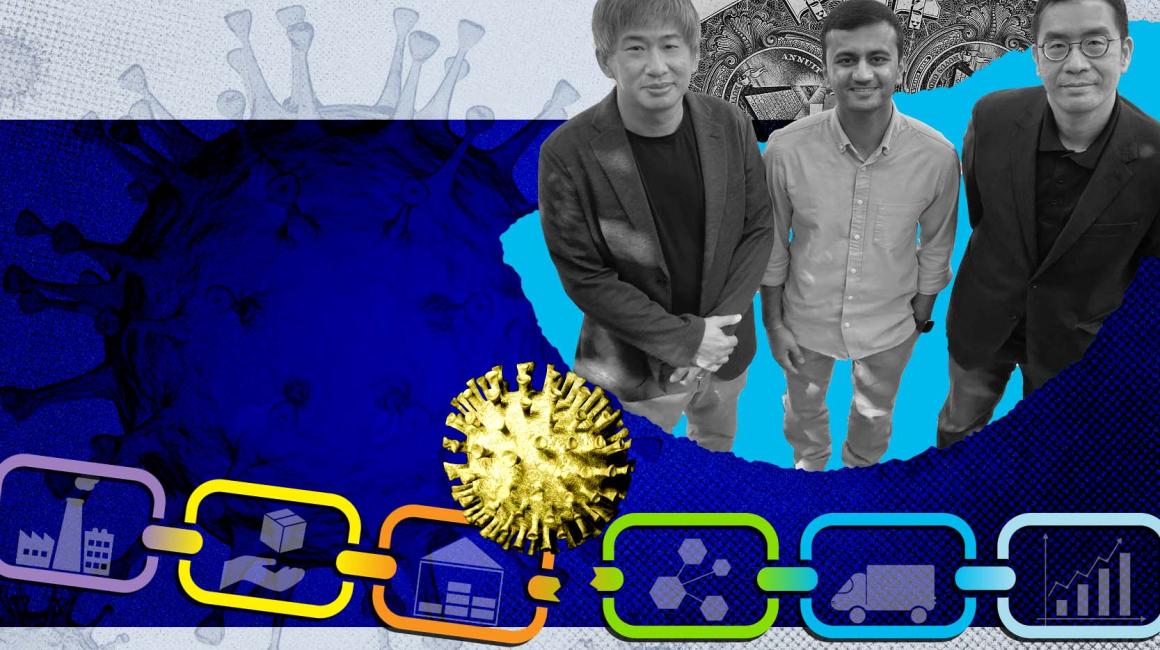

Mentored by UM-Dearborn College of Business Associate Professor Hung-Chung Su and Assistant Professor Wayne Fu, senior Siddharth Patel explored a potentially helpful financial solution that may ease supply chain strain — the “cash crunch” — for smaller suppliers during campus’ Summer Undergraduate Research Experience (SURE) program.

Talking with the three researchers recently, they explained that suppliers typically send an invoice that companies pay 60 to 120 days after receiving the materials. Companies receiving the products want to pay as late as possible; but the suppliers sending the productswant to get paid sooner than later. That’s typical supply chain practice.

“But when crises like the pandemic or weather-related instances happen, smaller supplies may find themselves in challenging situations and can’t wait for the payment to come 60 or 120 days later. They might be so strained that they are forced to go out of business. If suppliers are forced to close, companies may have trouble fulfilling demand and their sales may decrease. It’s a supply chain problem and an economic problem,” Su said. “There’s a relatively new and underresearched manufacturing finance practice that may be a win-win solution.”

Supply chain finance is when a third-party lender pays the supplier immediately after items are received for a small fee, instead of the supplier needing to wait the standard 60 to 120 days. And, in turn, the company receiving the materials pays the lender the invoice amount in the typical time frame.

Patel, a financial analyst intern for DTE who is majoring in finance and accounting, said learning about how companies handle spending and the financial options available is an interest of his.

“Supply chain finance is a good option for suppliers to look at to avoid feeling the cash crunch,” Patel said. “There’s often tension between suppliers and companies regarding when payment is received. Supply chain finance helps to mitigate the conflict for a small amount.”

Patel said he’s grateful to his COB professors who guided him through four months of research and that the research techniques and tools learned during the project will help him for his future career.

“I now understand how actual research happens and how to conduct it. The SURE program was very well defined and organized, and my professors were helpful and encouraging, which made it a very good learning experience,” Patel said.

Patel’s project on supply chain finance is one area of a larger issue, the professors said. In the future, they will continue exploring supply base concentration and supply chain resilience in their work.

Su said the pandemic exacerbated difficulties with suppliers getting access to raw materials, production facilities having worker shortages and shipping delays. With these in mind, businesses may want to take a step back to evaluate supply-related practices.

Typically, Su explains, companies have ‘just in time’ model inventory, which means you have little to no excess inventory — this is space effective and cost efficient. But maybe a ‘just in case’ model — that’s when you have excess on hand — may be an option for businesses to explore for supply chain resilience and to keep in-demand items in stock.

Fu, who worked in the supply chain management field for more than a decade prior to teaching, said one company practicing a more resilient supply chain model is 3M. With their localized manufacturing and having more surge capacity on hand, they were able to respond to needs quickly during the pandemic and were later recognized as “Supplier of the Year" by Supply Chain Dive.

However, resilience isn’t free — there’s a literal up-front cost. That’s why looking at cash crunch solutions and the feasibility of such options is important.

Professors Fu and Su said an efficient and flexible supply chain is an essential part of business. And they want to help local suppliers and manufacturers evaluate their supply chain practices, answer their questions or just hear from manufacturers or suppliers about challenges they are facing. Both professors said they are looking to work with industry and provide potential solutions.

“Local manufacturers are fighting to stay afloat. As part of this community, we want to bring our perspective and resources to help companies develop solutions,” Su said. “We are here, ready to listen and ready to help.”

If you are a business owner who would like to talk with the College of Business about your supply chain process, please contact Wayne Fu or Hung-Chung Su.