History will likely look back at the rapid development of the mRNA COVID-19 vaccines as one of modern medicine’s greatest success stories. Just one year after the coronavirus ignited a global pandemic, the first mRNA vaccines from Pfizer and Moderna were going into arms — breaking the previous vaccine development record, held by the mumps vaccine, by three years. Within another 12 months, tens of millions of people had received at least one dose, giving them highly effective protection against the virus. But this quick rollout of the most advanced vaccines was a story that mostly played out in higher-income countries. Part of that had to do with the high cost. But it was also rooted in logistics. Both of the mRNA vaccines required continuous cold storage all the way through the supply chain. The initial formulation of the Pfizer vaccine, in particular, required super cold storage of at least -60ºC from the moment it left the factory all the way to the pharmacy. When President Biden announced in June 2021 that the U.S. would send half of billion doses of Pfizer’s vaccine to the 100 lowest-income countries, it was understandably met with a bit of eye rolling in the NGO world and the Global South, since many countries on the list had extremely limited cold storage infrastructure. For example, NPR reported at the time that Sierra Leone, a country of almost 8 million people, had just one ultra-cold freezer. It was filled to capacity with Ebola vaccine.

This network of cold storage infrastructure — what’s known as the “cold chain” — is essential not only for vaccines but a wide variety of medicines, especially modern biopharmaceuticals. It’s also necessary for storing biological samples for research, as well as reagents, which are a common ingredient in lab tests. The idea that refrigeration keeps things fresh is so intuitive, it’s easy to think cold storage is simply one of medicine’s immutable realities. But a few years ago, UM-Dearborn Professor Pravansu Mohanty began to question how absolute this truth was. What if there was some way to keep vaccines and medicines from degrading without cold temperatures? If there was, that could change all kinds of things we do in medicine and research. It also had the potential to remove one of the biggest hurdles to bringing vaccines and advanced medicines to places off the cold chain grid.

Mohanty is not a physician or medical researcher by training, though his mother did want him to become a doctor. He might have followed that path had he been better at biology, but chemistry and physics were his stronger subjects, so he chose to study materials science and engineering. Still, his interest in biology, and human medicine in particular, has colored an eclectic, adventurous research career. For years, the mechanical engineering professor ran an advanced 3D-printing lab at UM-Dearborn, where one of his flagship projects was developing a process for creating custom titanium artificial joints for U.S. military service members. He saw 3D-printing’s capability to create one-off, ad hoc components as an obvious fit for human medicine, given that each person’s body is a uniquely configured machine. When Mohanty began working on the cold chain problem, he approached it with similar engineering sensibilities. Yes, the vaccines and medicines he was interested in were biological in nature, but at the end of the day, they were “just molecules.” In particular, they were mostly proteins. Proteins are often described as the “machines” of the cell, and it’s an apt metaphor. Just like human-engineered technology, a protein’s unique function owes a lot to its intricate hierarchical structure. “If you change the shape of a protein molecule, even slightly, likely it will no longer bind to a particular site and it won’t do what it’s supposed to do in the body,” Mohanty says. To preserve a protein, you have to preserve its structure.

This fact about proteins is what makes cold storage such an effective preservation technology. To jostle some memories from your high school physics course, temperature, on the molecular level, is fundamentally a measure of how much things are moving. At lower temperatures, atoms in materials move less than at higher temperatures, which is one reason why it’s easier for physical objects to maintain their shapes in colder conditions. In addition, cold slows down bacteria and chemical reactions that can degrade biological materials. But as a materials scientist, Mohanty knew that low temperatures weren't the only way to stabilize things. In particular, glass — not window glass, but glass as a class of materials with disordered molecular structure — can be an excellent stabilizer. In fact, glasses are often used to store very hazardous materials — even radioactive materials — because glass’ unique encapsulation power immobilizes things on the molecular level. Mohanty began to wonder if the right kind of glass could do the same for biological materials. That is, by surrounding the molecules of proteins with a glasslike substance, could he essentially immobilize their intricate structures, the way packing peanuts protect fragile items for shipping? Could he essentially “freeze” them in place — without the cold?

Even if he could, that would still only solve part of the problem. Since the goal was to preserve vaccines and medicines, his glass also couldn’t wreak havoc in the human body. And, of course, he’d also need a way of getting the desired proteins back out of the glass without damaging them. For years, he experimented with different materials and eventually found a group of polymers and sugar-based molecules with seemingly all the right properties. They could be used to form glass, and many were common vaccine preservation ingredients. Perhaps most interestingly, this glass could simply be dissolved in water. That meant releasing the biological materials wouldn’t require any special equipment or processes. It looked like a promising approach, though he says he was often filled with self-doubt. “You know, I’m not a formally trained biologist,” Mohanty says. “So my first thought was that this probably wasn’t real.”

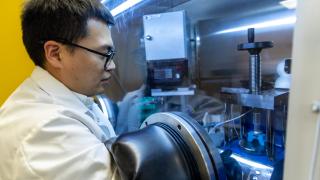

It turned out, however, that his team was onto something. Now six years into development, Mohanty’s unique biopreservation method has become the foundation for a biotech start-up, Upkara, which has an explicit mission to advance “global health equity.” Mohanty says starting Upkara, a Sanskrit word that loosely translates as “good deed,” has been a challenge unlike any he’s faced as a scientist and engineer. Over a more than two decade-long career, he’s won tens of millions of dollars in grants and earned many patents for his work. But starting a company has meant spending long hours trying to convince investors that this was indeed an idea that could have a profound impact on the world. “I am the kind of person who doesn’t enjoy things once they become routine, so starting this company has been an interesting learning experience,” Mohanty says. “In the beginning, of course, you are everything. You are the president, and the strategy person, and the recruiter, and you are also the person running the lab. You have to get good at telling your story to people, who have a lot of ways they could invest their time and money. You have to convince them that you have the edge over your competitors. You have to convince people this is real. Now I have people to help with all of that, and I am very thankful for all the support I’ve received, including from the university. I’ve enjoyed the challenge, although I could definitely not see myself becoming a CEO.” The curious scientist is still happiest in his lab.

For many startups, the ultimate goal is to score a big payday by selling the company to a bigger firm. But Mohanty has a different vision for Upkara. Rather than sell, they plan to license their biopreservation technology to anyone who wants it. Pharmaceutical companies have shown the strongest interest thus far, and Mohanty says Upkara, which currently operates from an incubation space on the UM-Ann Arbor campus, is on track to sign its first agreements with several clients this spring, including with at least one major American pharmaceutical company. However, by maintaining control of the core technology, Upkara will have the option to license it, at a sliding fee scale, to smaller entities, like government health agencies or NGOs in lower-income countries, which are in the singular business of helping people. If the company can make that vision a reality, it could potentially ease the cold chain problem by rendering it far less important — a remarkable achievement that would open up an alternative path for bringing advanced medicines to people in all corners of the world.

Mohanty says structuring the company around a social mission has surprised some of his friends and colleagues. “I’ve had people literally ask me how much money I’m making from all this,” he says. “But I’m not really someone who gets excited about the idea of selling something for a million dollars. For me, the thrill comes from creating, and the prospect that something can be so far-reaching. I mean, I’m happy with my life. The first home I bought when I became an assistant professor 24 years ago, that’s still my home. As a scientist, if I can make discoveries that help people, that’s plenty of satisfaction.”

###

You can read more about Upkara at the company’s website. Story by Lou Blouin