Facilities

The Human Centered Engineering Design program students will grow their theoretical and technical skills using state of the art facilities placed in their disposal. Students will have access to studios, makerspace and student project center to brainstorm, prototype and test.

The laboratory facilities, equipment and instrumentation available to support BSE in HCED program are listed below.

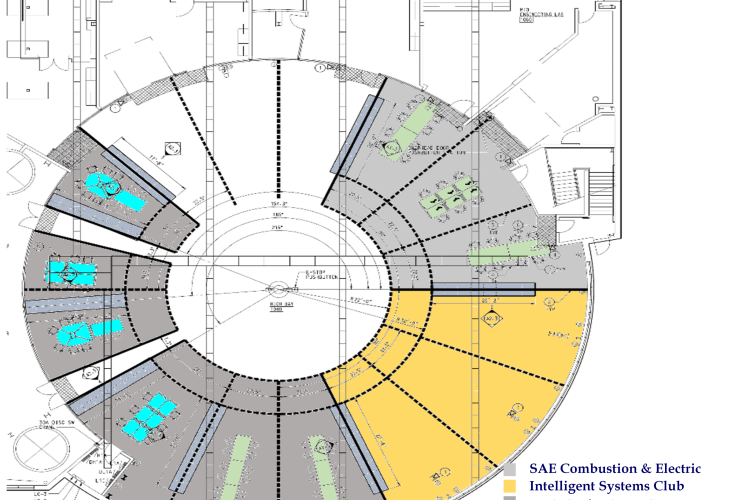

The IAVS Student Project Center

The IAVS Student Project Center serves as the collaborative student project team space for both curricular and co-curricular project teams. The space provides workbenches, tables with large monitors and chairs for collaborative work, 42” tall storage cabinets (lockers) to store work-in-progress. The lockers are also used to divide the different zones of the round space, as shown in the figure below. The space is also home to the CECS student competitive teams and clubs, including the SAE Formula Combustion team, the SAE Formula Electric team, and the Intelligent Systems Robotics Club, the Michigan Aeronautical Science Association-Dearborn. The teams utilize the space to assemble their competition products. Each of the student competitive teams has a dedicated section for work and assembly; however, fabrication is only performed in the fabrication facility housed in the Manufacturing Systems Engineering Laboratory (MSEL) Student Project Center.

MSEL Student Project Center

The Manufacturing Systems Engineering Laboratory (MSEL) Student Project Center (see Figure 1) offers the opportunity to apply classroom learning to real world problems through hands- on fabrication, multidisciplinary collaboration and exploration into materials and processes. The facility is also home to the CECS professional mechanical and electronic shops. The MSEL student project Center offers:

- A dedicated team of technician available to advise and mentor student teams.

- A variety of equipment and the ability to fabricate and join a wide range of materials.

- Training sessions to prepare users to operate equipment responsibly and safely.

- Supervised work hours that extend to late evenings and Saturdays.

The Center includes the following equipment:

- Training and classroom area for up to 24 students with reconfigurable benches.

- Student maker space that has the following capabilities

- 3-D printing: MakerBot PLA printers, FormLabs printers

- Welding/Cutting: TIG welding, MIG welding, resistance spot welding,CNC plasma cutting

- Basic metal-working: drills presses, sheet metal shear, metal band saw, sheet metal brake, grinding wheels, polishing wheel

- Wood working: Planer, shaper, table saw, panel saw, band saw.

- A variety of hand tools and measurement instrumentation.

- Professional machine shop: manual and CNC lathes and milling machines including HAAS CNC milling and turning centers

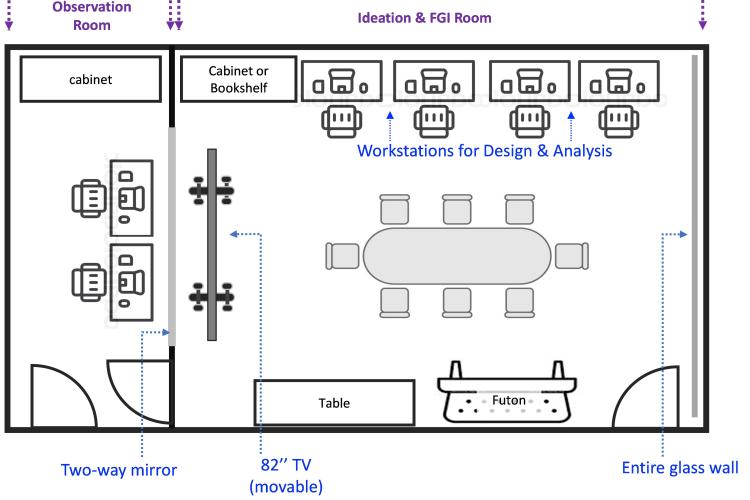

Human Centered Design and Engineering Design Studio

Two design studios of approximately 1,100 sq. ft. each will supports the BSE in Human Centered Engineering Design and MS in Human Centered Design and Engineering programs. Those space will be used for supporting the following activities: (1) practicum in industrial design including drawing and mock-up development, (2) brainstorming and ideation activities for development of creative artifacts, (3) development of UI/UX design prototypes including pencil-and-paper as well as high-fidelity working prototypes, and (4) evaluation of UI/UX system designs through usability studies and tests. The design studio are equipped with the proper furniture suitable for brainstorming and small scale prototyping activities. The design studio will also support: (1) instructional space for the design studio sessions in HCED 360, HCED 370, HCED 380, HCED 450, HCED 4951 and HCED 4952 courses, (2) brainstorming and ideation activities for development of creative artifacts, (3) informed design through quantitative and qualitative data collection, and (4) development of low, medium and high fidelity design prototypes.

Industrial Ergonomic Laboratory

The Industrial Ergonomics (IE) Laboratory is dedicated to improving safety and productivity in the designs of work environments and consumer products through both basic and applied research in ergonomics, occupational biomechanics, and work physiology. Other research efforts include, modeling behaviors of specific population, such as, older and obese workers. The IE laboratory is equipped with neuromuscular assessment devices (wired and wireless electromyography (EMG) device, functional muscle stimulator, Electroencephalography (EEG) system), motion capture systems (IMU-based and marker-based motion capture system), as well as force measurement devices (force platform, balance assessment system, and load cell).

Vehicle Ergonomics Laboratory

The work in this laboratory focuses on human factors research for design and evaluation of vehicle systems. The lab is equipped with various driving simulators to support human-machine interface (HMI) and human-vehicle interaction (HVI) research on flexible instrument clusters, the use of natural interactions (e.g., eye gaze and gesture) research in vehicle control, noble navigation aid system, and automated vehicles. The laboratory equipment include motion-based RTI (Realtime Technology, Inc.) driving simulator, realistic driver cockpit with flexible LCD cluster and simulated HUD (head-up display), eye tracking system, and human gesture recognition system.

Virtual Reality Lab

The newly proposed 1200 sq. ft. virtual reality (VR) Lab will serve as an educational facility for students to explore and learn cutting-edge VR and AR technologies. The lab will serve multiple purposes, including but not limited to:

- Prototype advanced digital models with a high level of fidelity

- Design and create ergonomic and interactive concepts/UX for virtual testbeds

- Simulate collaborative virtual assembly operation

- Create interactive data exploration in virtual environments

- Create virtual environments for various applications, such as museums, sports events, vehicle navigation, interaction between automated vehicles and pedestrians, flight simulation, workplace planning, training, education for disabled students.

The VR lab will be equipped with a Cave Automatic Virtual Environment (CAVE) system and other head-mounted devices, such as Oculus Go/Raft and HTC Vive. The CAVE system makes use of large, fixed screens more distant from the viewer for multiple users to collaborate and interact within the virtual environment. The head-mounted VR systems can be used in both in the lab and field studies, such as elementary schools for handicapped students. Other types of sensors will also be combined when the user is interacting with VR systems, such as Tobii eye tracking systems, physiological sensors (e.g., Shimmer for heart rate and skin conductance response) to collect other physiological data.

Engineering Laboratory Building

View of the ELB from Hubbard drive

The new ELB will be student-focused. It will be industry-driven and it is designed to inspire collaboration, innovation and cross-disciplinary teamwork. This 123,000 square-foot signature teaching and research laboratory building is designed to attract and retain the best and brightest faculty and students in high-demand and emerging fields. The ELB will be open for classes and laboratories in May 2021.